1、 Accurate matching of waterproof protection

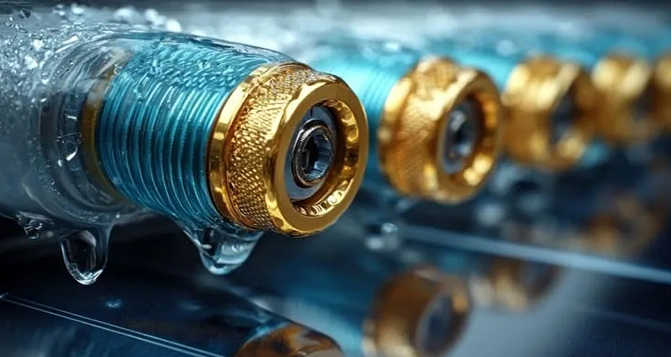

Modern connectors generally adopt an IP protection level system, but there are significant differences in the actual protection characteristics of different levels:

IP68 rating: suitable for long-term immersion environments (such as underwater equipment)

IP69K rating: designed to resist high-pressure steam cleaning (such as food processing equipment)

Selection key points: It is necessary to distinguish the application differences between "waterproof soaking" and "anti high-pressure spraying"

It should be noted that 90% of waterproof connectors only have protective capabilities when plugged in. For interfaces that are exposed for a long time (such as I/O ports of field monitoring equipment), special protective covers must be configured or special models with built-in sealing structures must be selected.

2、 Innovative Applications of Materials Engineering

Advanced plan for metal materials:

Aerospace field: Aluminum alloy shell treated with hard anodizing

Ocean engineering: It is recommended to use duplex stainless steel or copper nickel alloy materials

Cost optimization: Nickel plated copper alloy can replace precious metals in most scenarios

Breakthrough in Polymer Materials:

New type of polyetheretherketone (PEEK) material: resistant to temperature range of -60 ℃~250 ℃

Fiberglass reinforced nylon: Enhancing mechanical strength while maintaining lightweight

Conductive plastic composite material: EMI shielding function achieved through carbon fiber filling

3、 Engineering wisdom in structural design

The advantage of circular connectors in harsh environments stems from their physical properties:

Equal strength structure: uniformly withstand impact loads from all directions

Integrated sealing: A single O-ring can achieve full circumferential waterproofing

Electromagnetic compatibility: Faraday cage effect naturally formed by metal shell

Although military grade products (such as MIL-DTL-38999 series) have excellent performance, industrial grade alternatives (such as IP67 grade M12 connectors) can achieve 80% cost savings in scenarios such as automated production lines.

4、 Decision Model for Environmental Adaptation

Suggest establishing a four-dimensional evaluation system:

Chemical environment: pH value, salt spray concentration, oil pollution level

Physical stress: vibration spectrum, impact acceleration, insertion and extraction frequency

Climate conditions: temperature cycling range, ultraviolet intensity, condensation risk

Electromagnetic environment: RFI intensity, ground potential difference, shielding requirements