When the driver turns the steering wheel or steps on the brake pedal, an invisible electronic system is converting mechanical actions into precise digital commands at millisecond speeds. This is X-by-Wire - the most core "electronic nervous system" of modern cars, which not only redefines the way vehicles are controlled, but also lays a key foundation for the era of autonomous driving.

Three layer architecture: from mechanical linkage to electronic signals

The core of wire control technology lies in replacing traditional physical and mechanical connections with electronic signal transmission, and this revolutionary change is achieved through three closely coordinated levels.

At the intention perception layer, high-precision sensor networks convert the driver's mechanical operations into quantifiable digital signals. The photoelectric encoder under the steering wheel can accurately measure the steering angle up to 0.1 degrees, while the torque sensor captures the magnitude of the torque applied by the driver in real time. The linear displacement sensor in the brake pedal system records the percentage of pedal travel, while the torque sensor collects the pedal force value. These sensors collectively complete the conversion from human fuzzy operation intentions to precise digital signals.

The decision processing layer is like the brain of the system, where the electronic control unit (ECU) performs complex real-time arbitration. It comprehensively processes information from multiple sources, including vehicle status parameters, road environment data, and possible autonomous driving commands. To ensure absolute reliability, multiple security mechanisms are adopted at this level, such as dual core lockstep technology to ensure consistency of operations, and watchdog circuit to monitor the health status of the system.

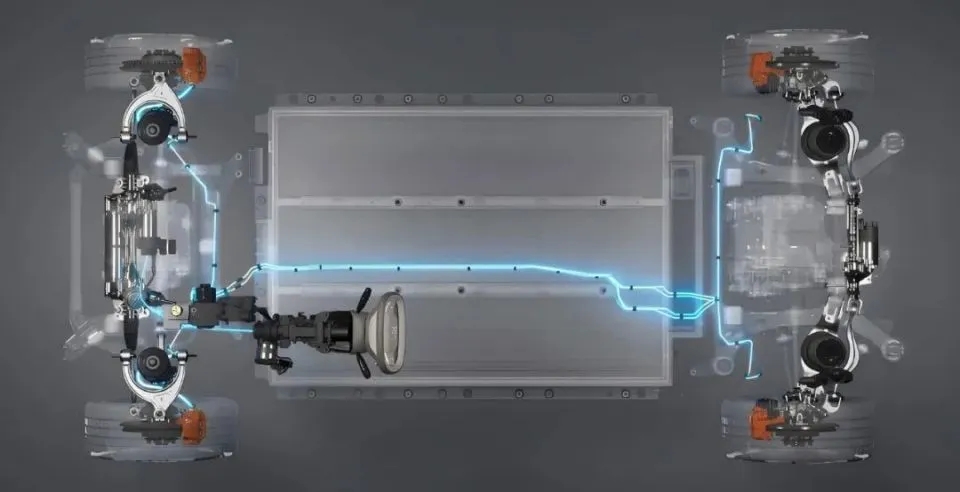

The final execution layer is composed of high-precision electronic drive mechanisms. In the online control steering system, the brushless motor drives the steering rack to move precisely through the planetary reduction gear set and worm gear mechanism; The wire controlled braking system distributes independent braking force to all four wheels through an electronic hydraulic pump and solenoid valve array. These execution mechanisms all adopt redundant design to ensure that a single failure will not result in complete system failure.

The neural basis of autonomous driving

The importance of line control technology for autonomous driving is reflected in its millisecond level response capability. The traditional hydraulic braking system requires 300-500 milliseconds to complete the braking action, while the wire control system compresses the full response time to within 50 milliseconds. When the auto drive system detects pedestrian crossing at a speed of 80km/h, this rapid response can shorten the braking distance by 1.2m and reduce the collision probability by 22%.

Mechanical decoupling brings revolutionary design freedom. After removing the steering column, the front of the cockpit can increase knee space by 150mm and support innovative designs such as a storable steering wheel. The wire control system has also achieved significant lightweighting, with traditional hydraulic brake components weighing about 23kg, while the wire control brake module weighs only 10.8kg. For electric vehicles, the coordinated control of electronic braking and regenerative braking can increase range by 8-15%.

Technological breakthroughs from laboratory to mass production

Pushing line control technology to the market faces multiple challenges. Functional safety certification needs to cover over 2000 fault scenarios and complete millions of kilometers of testing. The Bosch second-generation iBooster line control system passed the highest safety level ASIL-D certification in 4 years and was tested on 217 vehicles.

The issue of electromagnetic compatibility (EMC) is equally severe. Engineers adopt measures such as embedding copper mesh shielding layer in three-layer PCB boards and installing ferrite magnetic rings on wiring harnesses to ensure stable operation of the system in complex electromagnetic environments. The entire machine must undergo rigorous radiation immunity testing to demonstrate its ability to resist strong electromagnetic field interference of 200V/m.

In terms of user experience, the line control system has achieved unprecedented precision control. It can automatically adjust the frequency of braking intervention according to road conditions and increase steering damping to improve stability during high-speed driving. When the system detects a fault and switches to the backup unit, it will maintain pedal reaction force through motor simulation to avoid discomfort to the driver.

The future cornerstone of software defined cars

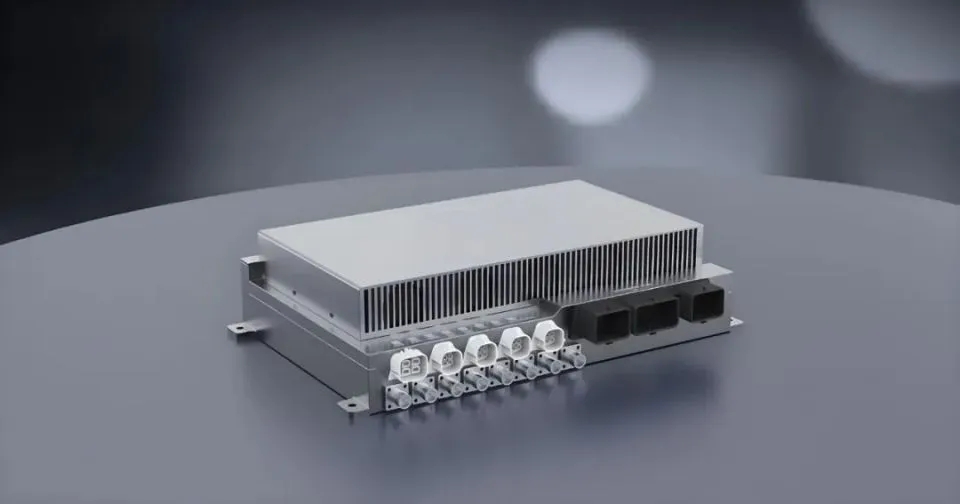

Line control technology is driving the evolution of automotive electronic architecture from distributed to domain centralized control. The new generation chassis domain controller integrates steering, braking, and suspension control algorithms, compressing communication latency to within 1ms through a time sensitive network (TSN). The EVA domain controller equipped on the Mercedes EQS has achieved synchronous calculation of active suspension and torque distribution.

The introduction of artificial intelligence makes predictive maintenance possible. The system continuously monitors the characteristic parameters of the actuator and predicts potential faults through cloud models. This capability can reduce maintenance costs by 30% and significantly improve vehicle availability.

The OTA upgrade function enables the continuous evolution of the line control system. Manufacturers can push new steering feel curves, optimize braking algorithms, and even adjust control strategies based on regional road conditions. In the future, combined with V2X technology, the line control system can receive infrastructure signals, automatically calculate the optimal driving speed, and achieve a control accuracy of ± 0.5km/h.

Conclusion: The paradigm shift from mechanics to electronics

The wire control technology has fundamentally transformed the automotive control system - converting mechanical actions into high-speed flow of electronic signals, and then achieving precise execution through intelligent algorithms. This' electronic nervous system 'not only meets the stringent requirements of autonomous driving, but also breaks the physical limitations of traditional car design.

When the ECU continues to learn driving habits, when the braking system avoids danger within one percent of a second, and when the steering wheel automatically stores during autonomous driving, wire control technology has quietly become the "invisible driver" of smart cars. This technological revolution, which began with aviation flight control, is driving the historic leap of automobiles from steel machinery to electronic intelligent agents.